Maximum Productivity in

Extreme Underground Conditions

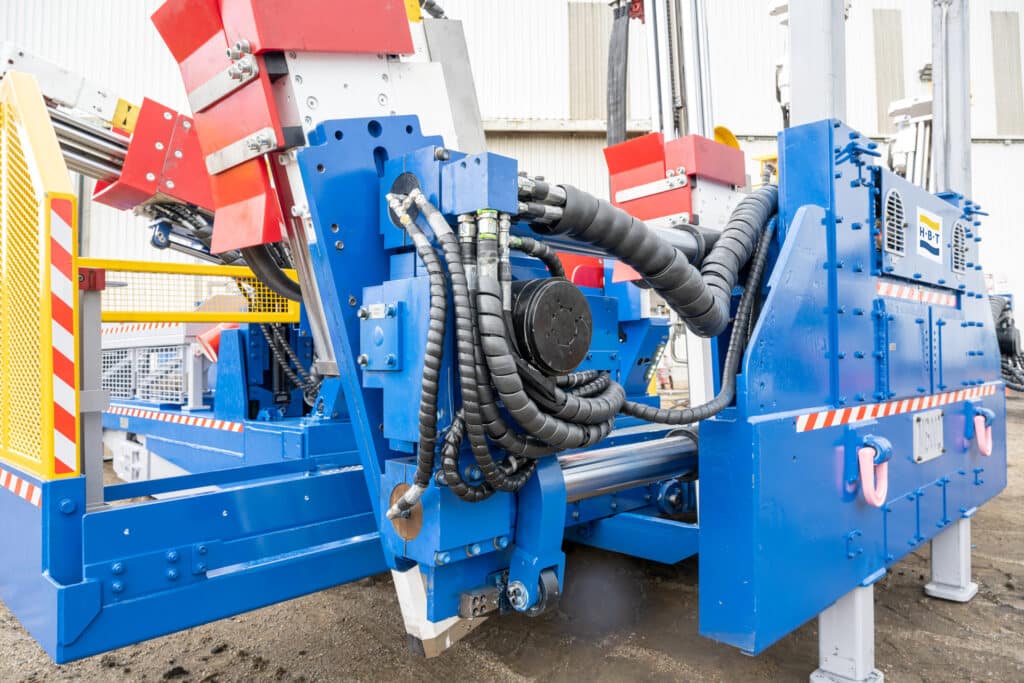

Developed in close collaboration with Australian underground mining operations, HBT’s mobile bolters are engineered to reduce operator fatigue and deliver exceptional performance. From the streamlined platform layout to the intuitive control interface, our engineers have designed an ergonomic machine that performs efficiently in confined spaces and under the harshest conditions.