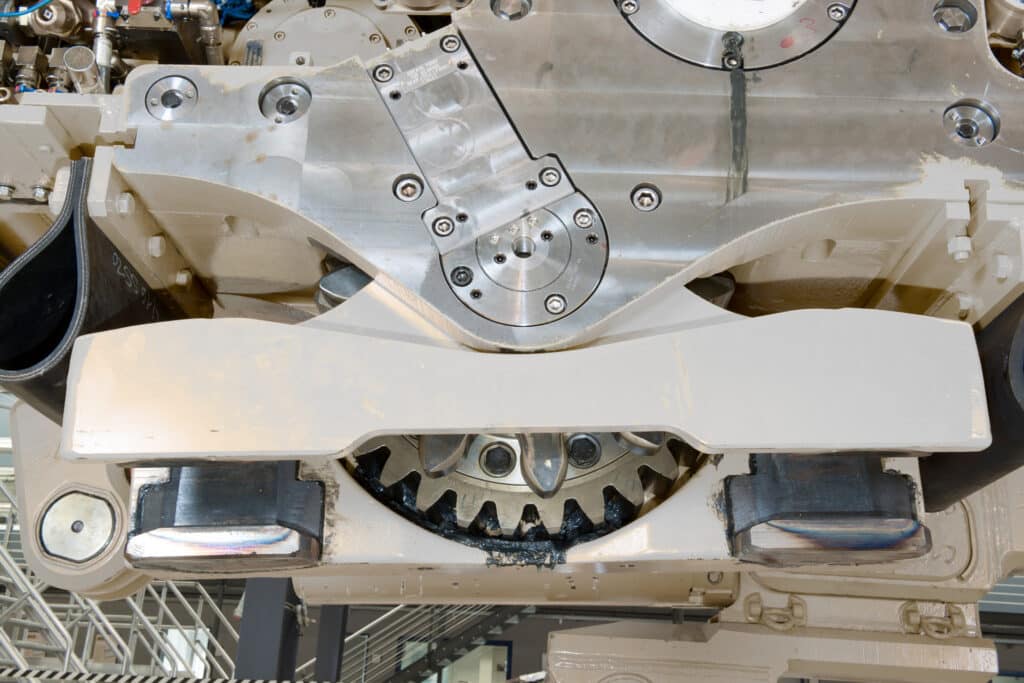

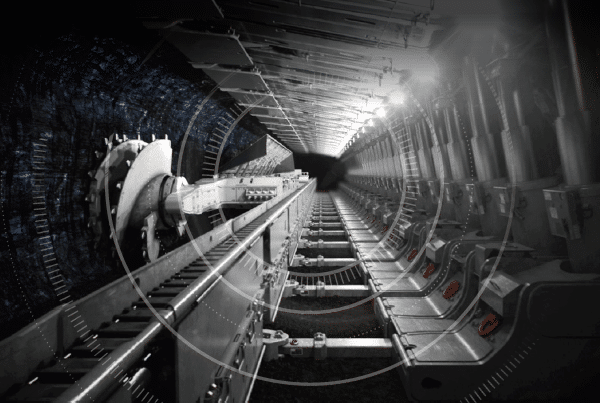

HBT Shearers

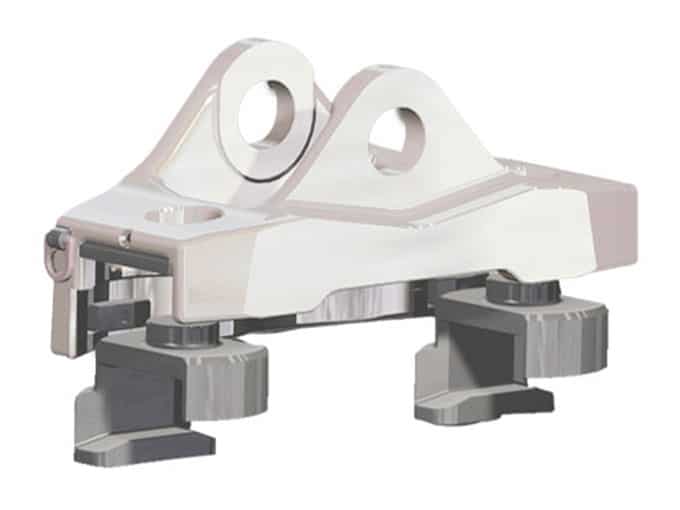

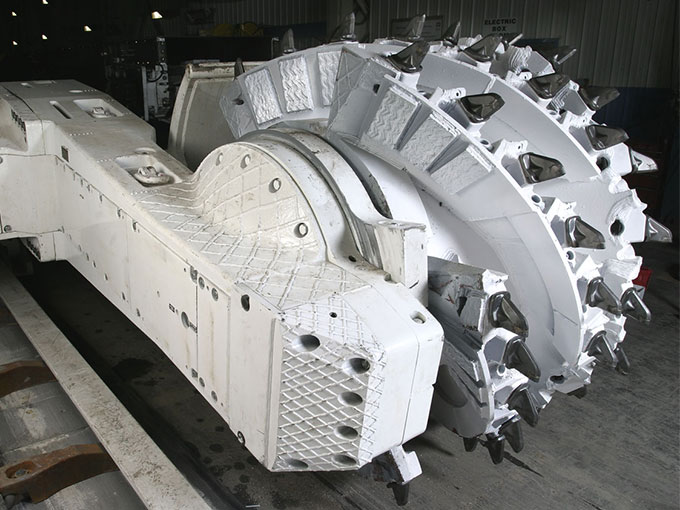

Coal panels and face lengths are increasing – the average seam height is not. Maximizing productivity levels as the seam height diminishes requires a robust and compact cutting machine design with optimal coal-loading performance –

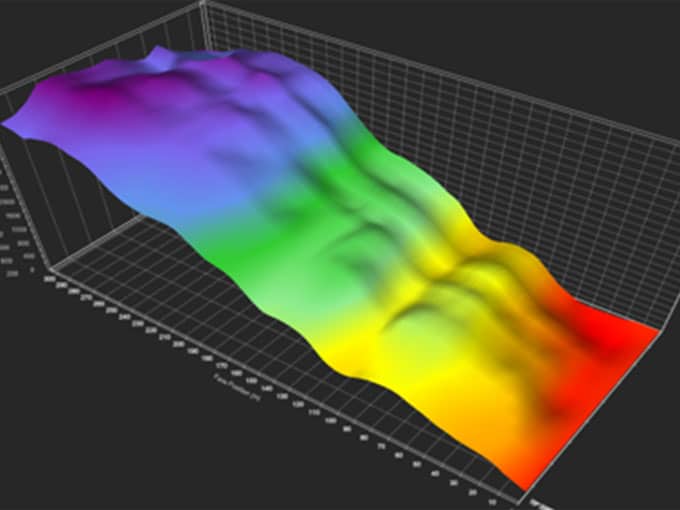

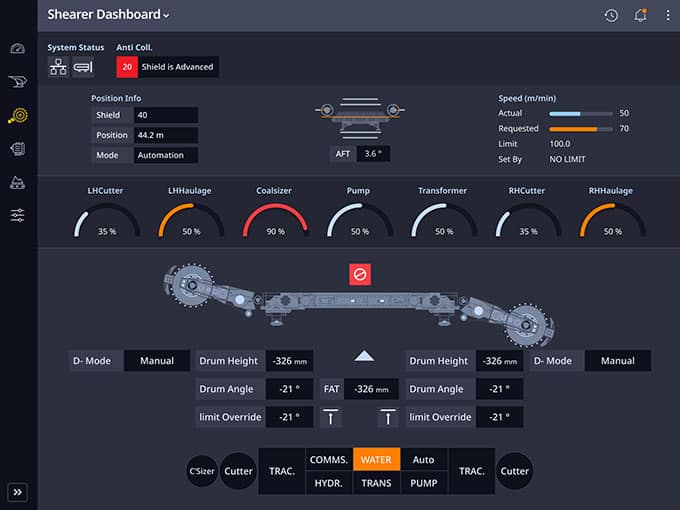

backed by advanced automation capabilities for visualization and control.