CST DRive Systems

Intelligent CST Drive Systems

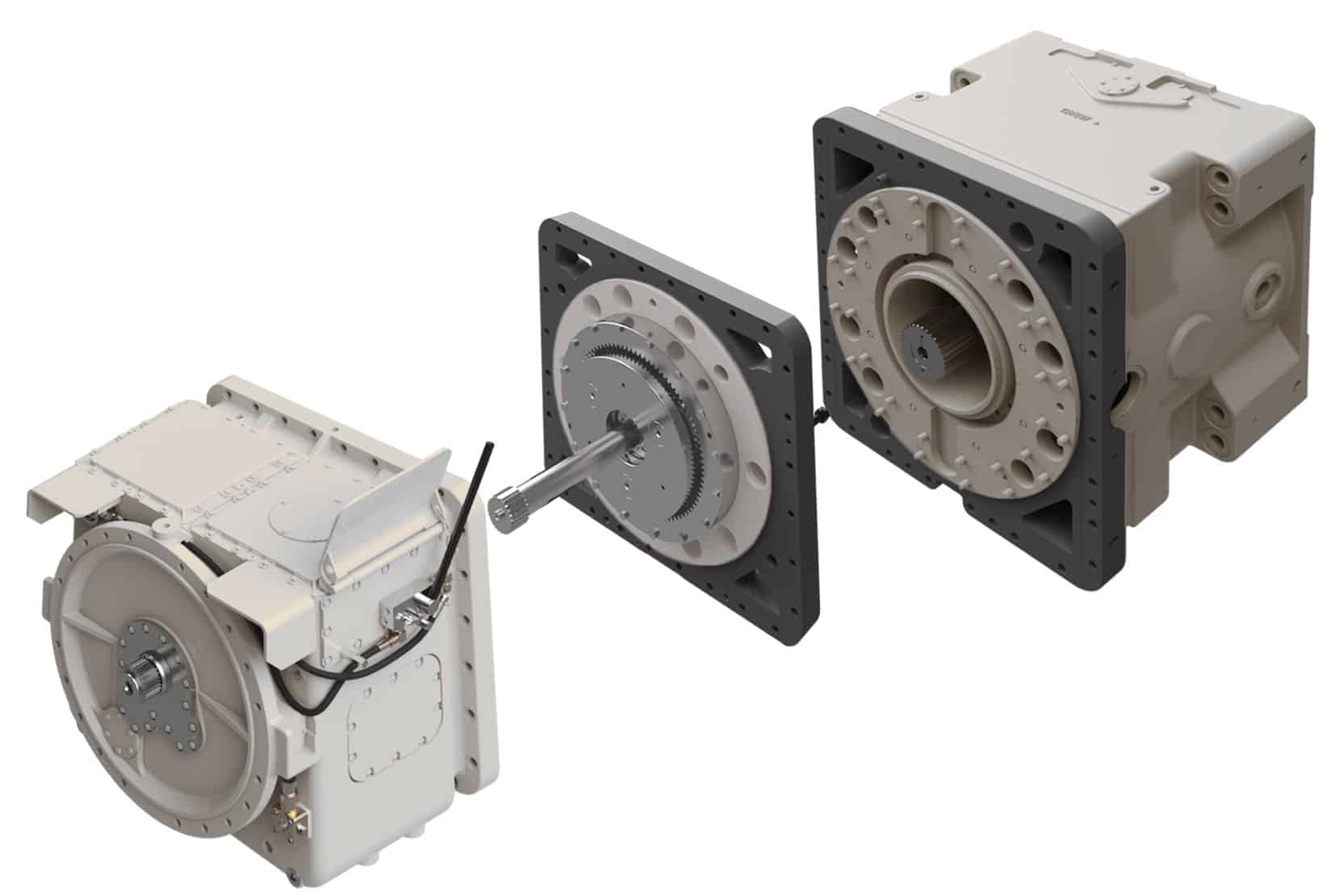

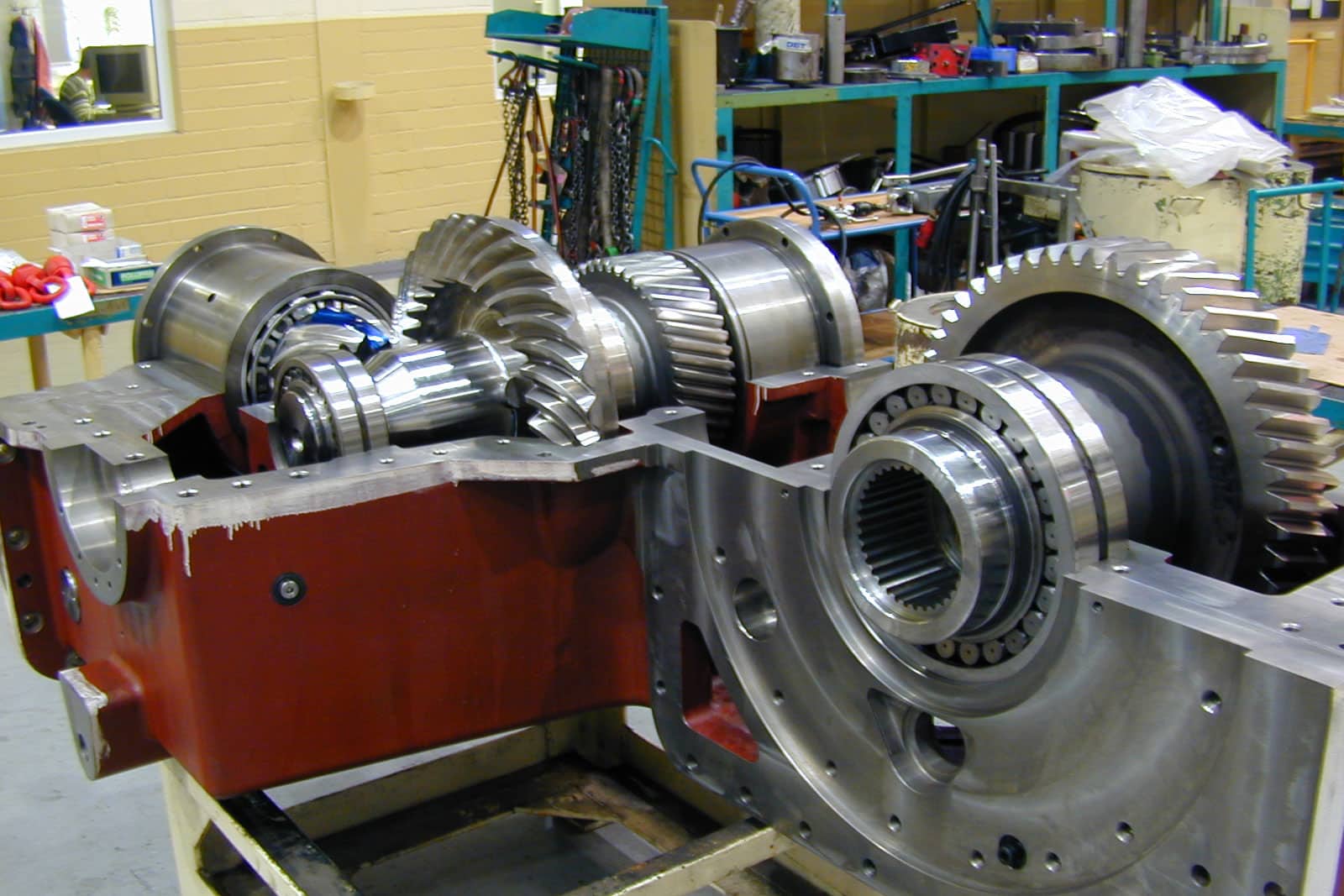

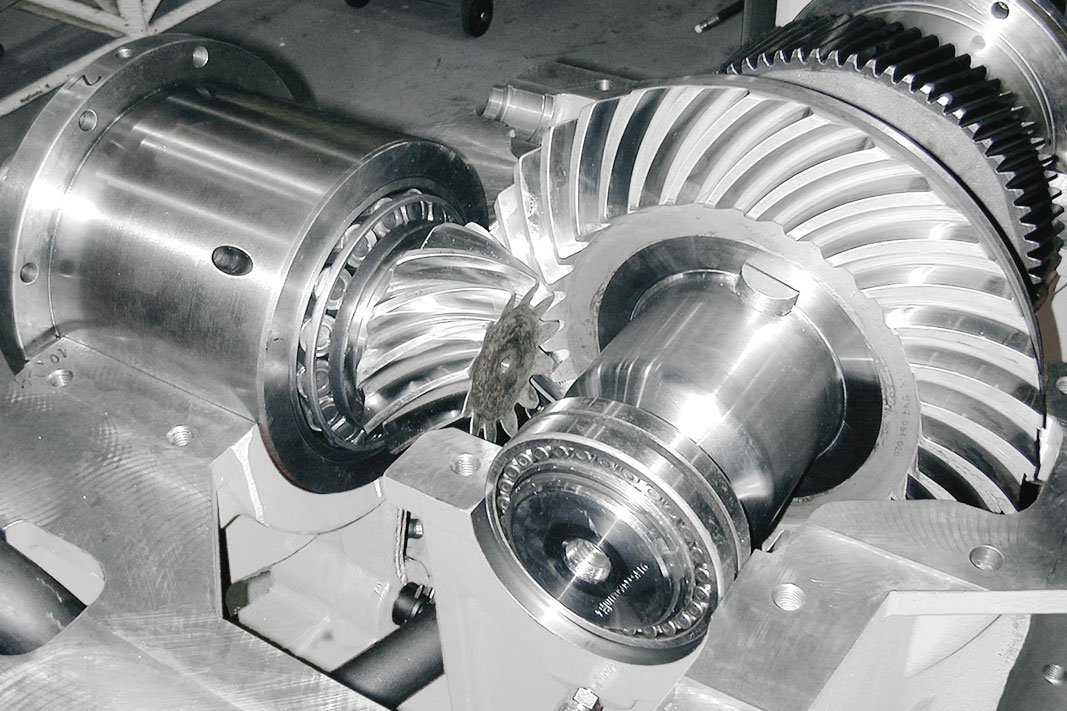

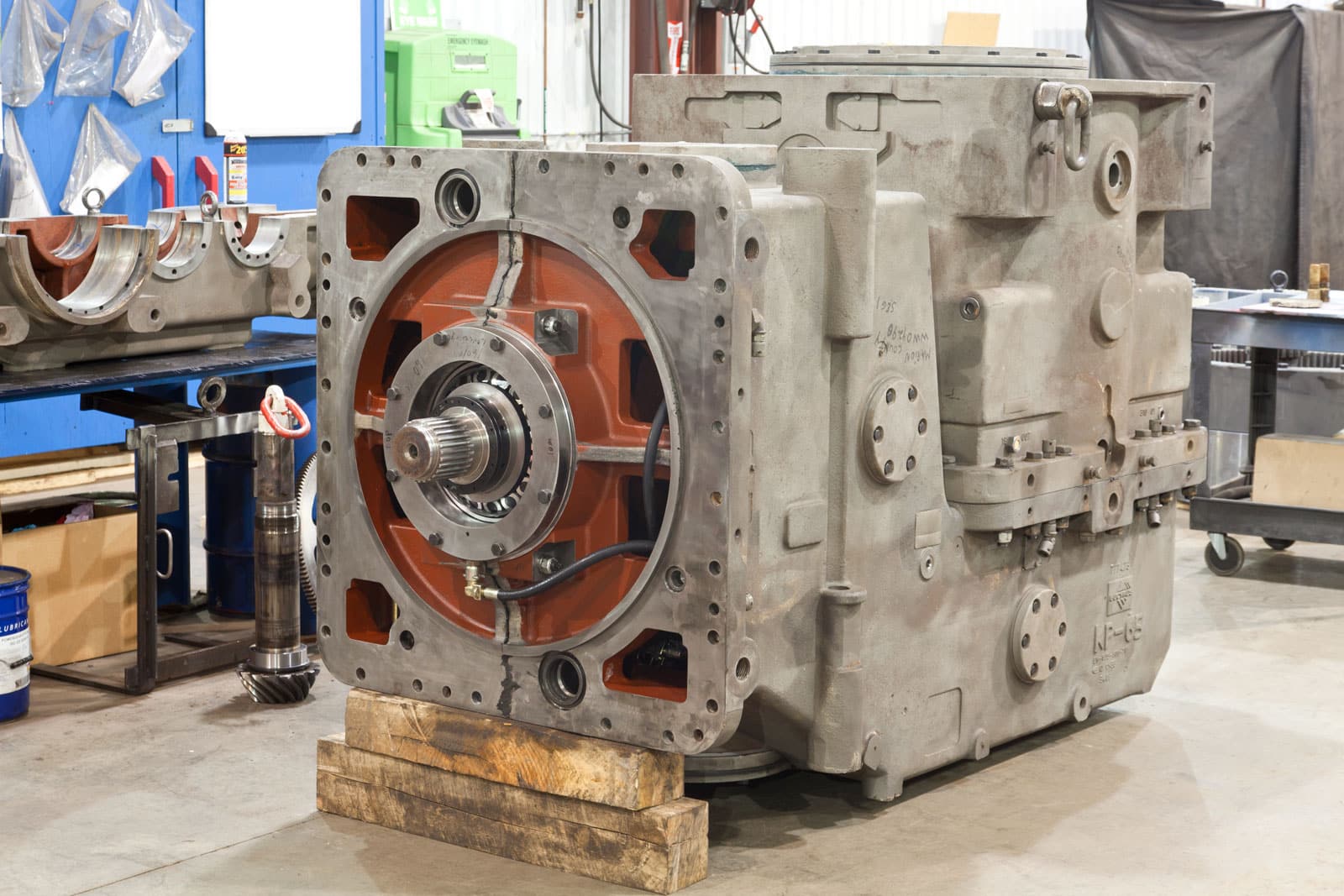

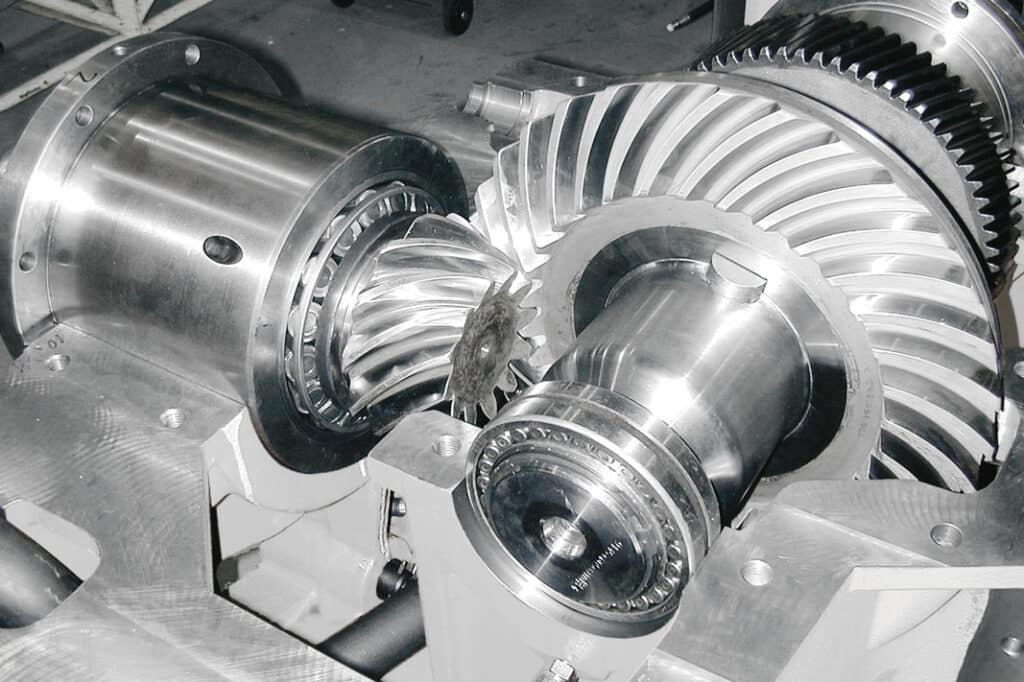

The HBT CST (Controlled Start Transmission) is a 2 in 1 drive which combines a planetary gear reducer with an integrated infinitely variable multi-disc clutch system. When coupled to an AC induction motor, the CST reduction gears convert the motor’s high-speed, low-torque input to a low-speed, high-torque output. The integrated clutch provides smooth, controllable power suitable for direct coupling to a high inertia load, such as an armored face conveyor.

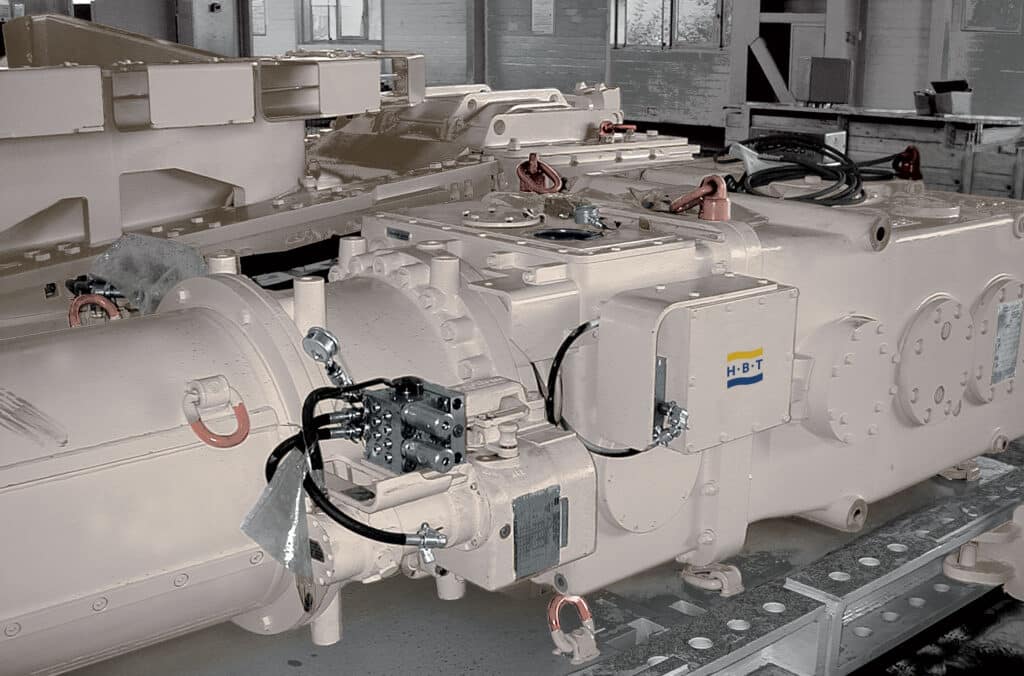

The HBT CST drive is a very cost-effective solution, engineered specifically to deliver total control of the most difficult high inertia loads such as long face conveyor systems (400 m and more), and conveyors with multiple synchronized drives. The CST drive provides efficient transmission of motor power and torque with consistent smooth acceleration and deceleration, regardless of varying loads on the conveyor or ambient conditions.