Technical Data | | |

Line Pan Width

PFHD/1062

PFHD/1162

PFHD/1262

PFHD/1362 |

1062 mm

1162 mm

1262 mm

1362mm |

41.81 in

45.75 in

49.69 in

53.62 in |

Flightbar Widthbr>PFHD/1062

PFHD/1162

PFHD/1262

PFHD/1362 |

888 mm

988 mm

1088 mm

1188 mm |

34.96 in

38.89 in

42.83 in

46.77 in |

| Deck Plate Thickness | 60 mm

70 mm | 2.36 in

2.76 in |

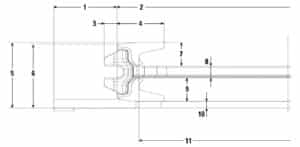

| Profile Height | 398 mm | 15.67 in |

| Bottom Plate Thickness | 30 mm

40 mm | 1.18 in

1.57 in |

| Dogbone Breaking Strength | 4500 kN | 505.82 tonf |

| Dogbone Housing FoS | 1.5 times | 1.5 times |

| Shear Strength | > 6000 kN | > 674.42 tonf |

| Vertical Articulation | up to ± 6° | up to ± 6° |

| Horizontal Articulation | 0.8°-1.2° | 0.8°-1.2° |

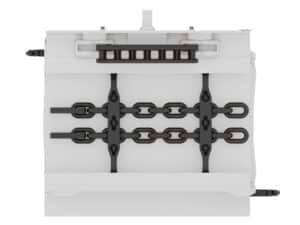

| Chain Strands | DKB 42×146

DKB 48×160/144

DKB 52×127/170

DKB 60×181/197 | DKB 42×146

DKB 48×160/144

DKB 52×127/170

DKB 60×181/197 |

Conveying Capacitybr>PF6/1042

PF6/1142

PF6/1242

PF6/1342 |

approx. 0.58 m2

approx. 0.64 m2

approx. 0.72 m2

approx. 0.85 m2 |

approx. 6.24 ft2

approx. 6.89 ft2

approx. 7.75 ft2

approx. 9.15 ft2 |