Programmable Mining Control

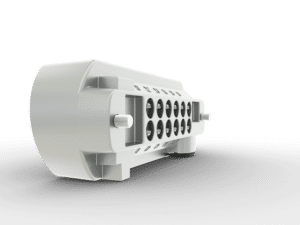

PMC-R 2.0

The HBT PMC-R 2.0 system represents the next-generation, state-of-the-art HBT automated control unit for longwall roof support applications. Based on the successful predecessor PMC-R, it combines the best features of that system with additional features required by longwall operations. The result is an innovative electrohydraulic shield control contributing to full automation of the advancing longwall.

Application

The intrinsically safe PMC-R 2.0 control units are specifically designed to be used on shearer or plow faces to provide high levels of longwall automation.

Each roof support is equipped with one PMC-R 2.0 control unit and solenoid driver to operate the in-shield hydraulic functions and peripheral components, such as sensors for cylinder pressure and stroke length, shield inclination and personnel proximity detection.

The PMC-R 2.0 unit controls and displays all functions of a roof support and serves as the interface between operator and machine (HMI).